DION uPVC Tile Sheet

DION UPVC sheets are optimum choice for roofing & cladding. uPVC roofing sheets is the best replacement to conventional asbestos, metal G.I: sheets, fiberglass sheets and ceramic tile sheets, considering its property of heat insulation, sound insulation, water resistance, chemical and alkali resistance, corrosion proof, fire retardant, eco friendly. They are easy to install and move. Light weight as well as cost effective in installation.

DION Quality & Aesthetics - A perfect combination to match your roofing needs.

MATERIAL STRUCTURE

1. Surface Layer - The material is ultra-weather resin, to block the solar ultra violet and reduce the coefficient of heat conductivity, ensure product durability and resistance to chemical corrosion.

2. Surface Intermediate Layer-contains Multi foam giving to the material light weight and improved sound and thermal insulating properties.

3. Underlying layer - for just a good material toughness special to ensure the strength at the same time, increase the rigidity and light illumination.

Three kinds of different materials to give the product their own features and the organically combined to make a new generation of heat insulation uPVC sheet to solve theproduct durability, corrosion resistance, small rigidity, a sense of space and aesthetics issues.

DESCRIPTION

| Profile Name | Thickness (mm) | Width (mm) | Length | Color |

|---|---|---|---|---|

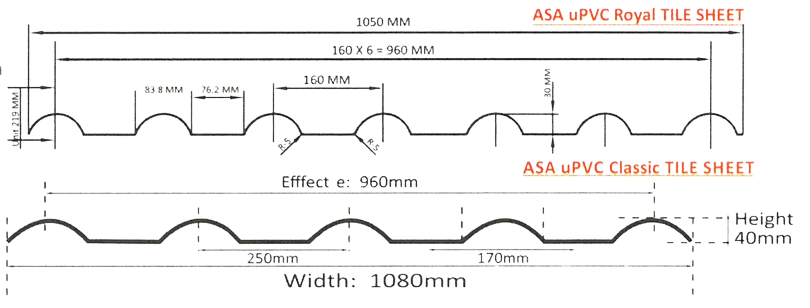

| ASA uPVC Royal Tile Sheet | 2.3, 2.5 | 1050 | 2.41, 3.07, 3.73, 4.38, 5.03, 5.47, 6.13 Mtr. | Gray & Terracotta |

| ASA uPVC Classic Tile Sheet | 2.3, 2.5 | 1080 | 2.50, 3.0, 3.75 Mtr. | Gray & Terracotta |

Weight (Approx): 2.6kg per square meter (1.5mm) 3.4 Kg per square meter (2mm), 4 kg per square meter (2.5 mm), 5.1 kg per square meter (3mm) 5.8 kg per square meter (3.5 mm), 6.3 kg per square meter (4mm)

Purlin Span: 1.5mm < 1.5feet, 2mm < feet, 2.5 mm < 2.5 feet, 3mm < 3 feet, 3.5mm < 3.5 feet, 4.0 mm < 3.5 feet

PROPERTY TEST METHOD VALUE

| Sr. No. | Test | Test Method | Unit | Results Obtained |

|---|---|---|---|---|

| 1 | Vicat softening temperature at 1kg. | ASTM 1 1525 | °C | 93.5 |

| 2 | Vicat softening temperature at 1.8Mpa | ASTM D 648 | °C | 69.2 |

| 3 | Vicat softening temperature at 66 PSI. | °C | 77.2 | |

| 4 | Vicat softening temperature at 364 PSI. | °C | 69.2 | |

| 5 | Flammability | UL-94 | Math with vo | |

| 6 | Rate of burning | ASTM D 635 | The flame front did not reach the 25 mm ef. mark | |

| 7 | Tensile strength at break | ASTM D638 | MPa | 30.63 |

| Elongation at break | % | 130 | ||

| 8 | Flexural strength | ASTM D 790 | MPa | 73.3 |

| 9 | Resistance to chemical (10% H2SO4 for 24Hrs.) | ASTM 0 543 | No visible changeobserved | |

| 10 | Density | ASTM D 792 | gm/cc | 1.56 |

| 11 | Water absorption (change in mass, 24 Hrs.) | ASTM D 570 | % | 0.07 |

| 12 | Charpy impact | ASTM D 6110 | KJ/m2 | 8.1 |

| 13 | Themal resistance | At 70°C/72Hrs. | No effect | |

| 14 | Chemical resistance | In 18% HCL/24Hrs | No effect | |

| 15 | Chemical resistance | In 20% NaOH/24Hrs | No effect | |

| 16 | Chemical resistance | In Saturated CaCl2/24Hrs | No effect |